ABOUT US

ZAK Steels Producing

Since 2000 in Rawat, Islamabad

ABOUT US

ZAK Steels Producing

in Rawat, Islamabad

ZAK Steels is one of the largest steel producers in Rawat, Islamabad. Being a renowned name in the Steel Bars manufacturing industry, believing in continuous modernization, innovation and manufacturing of quality steel bars has enabled us to maintain the production capacity of more than our fully automatic state of the art plant with complete European machinery, as per International Standards.

Grade 40 & 60

(ASTM A615)

Deformed Steel Bars

Mazboot Bunyad,

Mahfooz Mustaqbil

Since its inception ZAK Steels has produced thousands of tons of quality steel bars and catered to more than a million clients thus creating a brand in the steel industry which no other name could match. Our reputation in the steel industry is that of the pioneers in steel making. The vision of the company is to make the finest quality steel bars at a reasonable price thus adding value in the society’s infrastructure. Our steel is used in buildings across the nation, from tall towers to famous landmarks, from airports to railway stations and from shopping malls to residential houses.

Few of the mega structures that ZAK Steels supports today are just a few of many extra ordinary structures whose foundations were laid with ZAK Steels re-bars and they continue to stand tall with pride as integral monument adding value to the skylines of this nation.

ZAK Steels

In a Glance

Our steel bars sustain long period of corrosion and rust free with having proven record in resisting loss of strength at high temperatures, making ideal choice in construction of mega projects.

Our Steel bars have elongation of more than 14% which makes ideal choice for earthquake prone areas and High Yield Strength Grade-60 resulting in lesser steel consumption, as high as 15-24%

Our Grade-40 and Grade-60 Steels bars are approved with PSQCA, certified with ISO 9001 and leading supplier of top mega structures including Bahria Town.

We maintain the highest quality of international standards with its In-house latest computerized Servo Controlled Laboratory and German Spectrometer for 100% quality assurance of its produced steel bars.

With the fully automatic plant, our production capacity of over 150,000 m.t / annum enabling ready and fast delivery system direct from our steel mill.

We are the largest producer of Grade-40 & Grade-60 Steel bars in Rawat, Islamabad using 100% Hot Rolled Billets as raw material.

Spectro Lab

The Spectro Lab Determines the Physical

& Chemical Composition of the Steel Bars.

Mechanical Lab

Universal Tensile Testing Machines.

With a well-equipped laboratory and professional manpower to assure the quality of our products. We have adequate inspection & chemical testing procedure starting from procurement of raw materials to manufacturing of finished product.

State of the art hydraulic controlled Universal Tensile Testing Machines of 1000KN conduct a stress test on the steel bar at regular interval, and gives readings of the proof test, tensile stress and elongation ensuring that the re bars manufactured at our facility conform to the strictest quality standards.

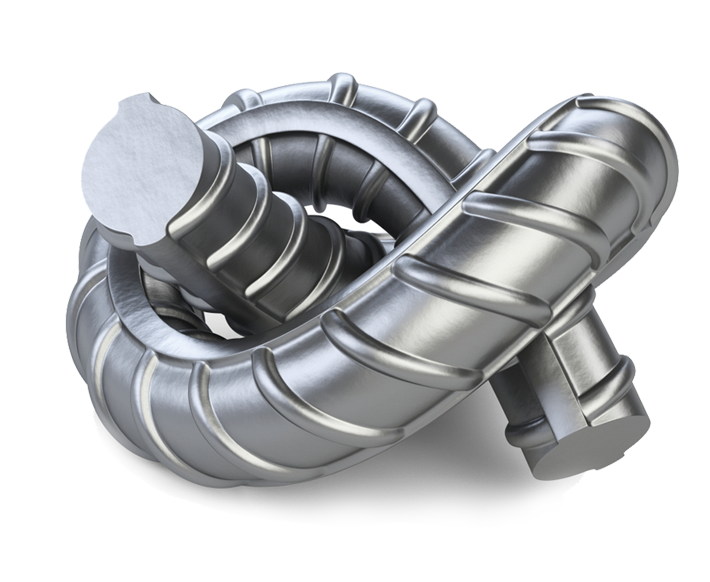

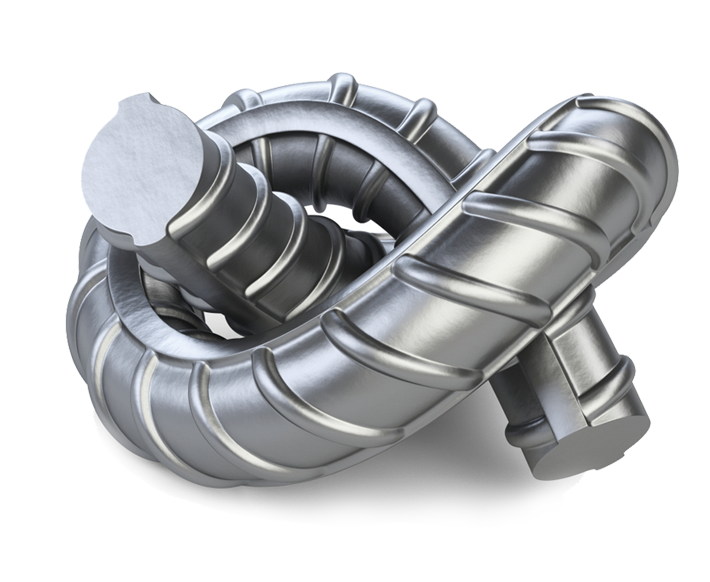

ZAK STEELS PROCESS

Making innovations possible by fusing together with

technology turning strong foundation, safer future.

QUENCHING

The hot rolled bar leaving the final mill stand is rapidly quenched by a special water spray system. This hardens the surface of the bar to a depth optimized for each section through formation of martensitic rim while the core remains hot and austenitic.

SELF TEMPERING

When the bar leaves the quenching box, the core remains hot compared to the surface allowing heat to flow from to the surface causing tempering the outer martensitic layer into a structure called Tempered Martensite. The core still remains austenitic at the stage.

ATMOSPHERIC COOLING

This takes on the cooling bed where austenitic core transformed into ductile ferrite pearlite structure. Thus the final structure consists of an optimum combination of strong outer layer (tempered martensite) with ductile core (ferrite pearlite). This gives Universal TMT its unique combination of higher strength and ductility.

Quality Assurance

That Matters.

SOME OF THE TOP

ARCHITECTS, BUILDERS & CONTRACTORS

THEY TRUSTED ON ZAK STEELS

Durability in their Construction Projects

OUR PRIDE

Certified With